PET is the abbreviation of English Polyethylene terephthalate. It means polyethylene terephthalate plastics, mainly including polyethylene terephthalate PET and polybutylene terephthalate PBT. Polyethylene terephthalate is also commonly known as polyester resin.

PET plastic structure

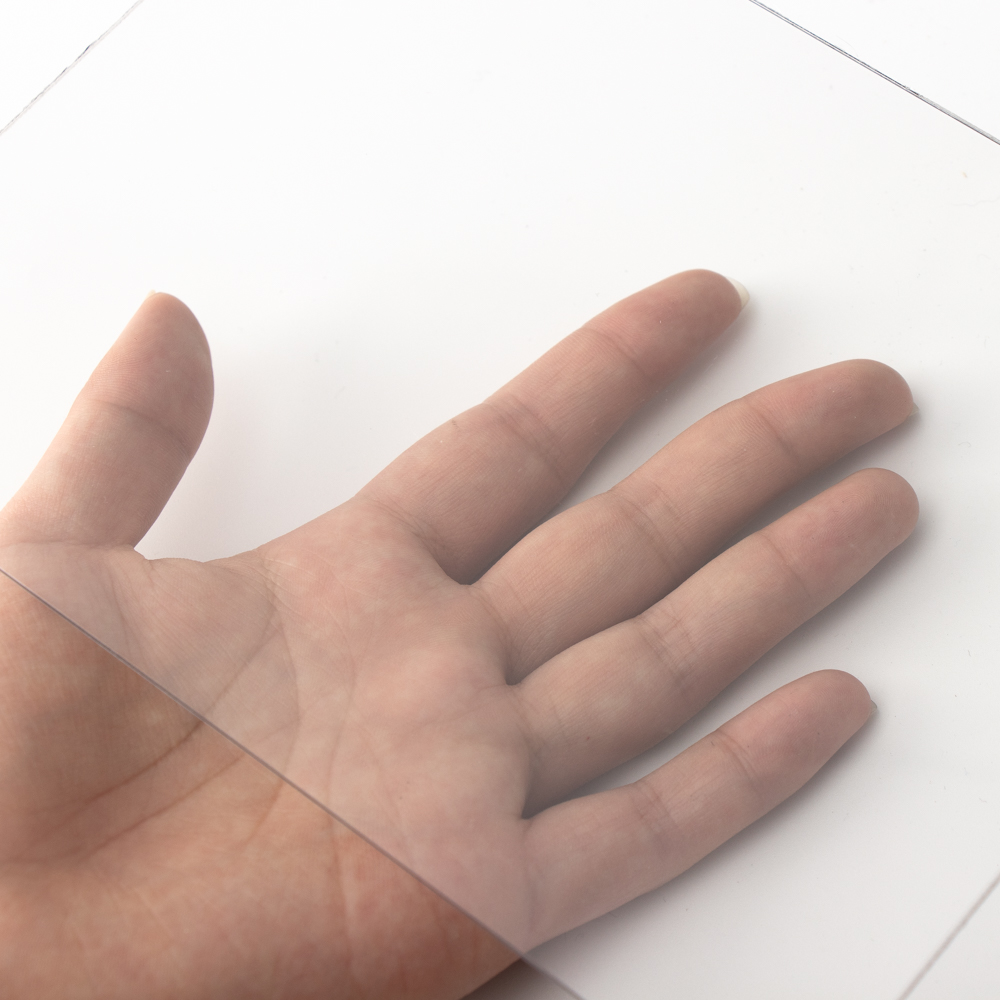

The molecular structure of PET plastic is highly symmetrical and has a certain crystal orientation ability, so it has high film-forming and forming properties. PET plastic has good optical properties and weather resistance, and amorphous PET plastic has good optical transparency.

![PET Transparent Sheet (9)]()

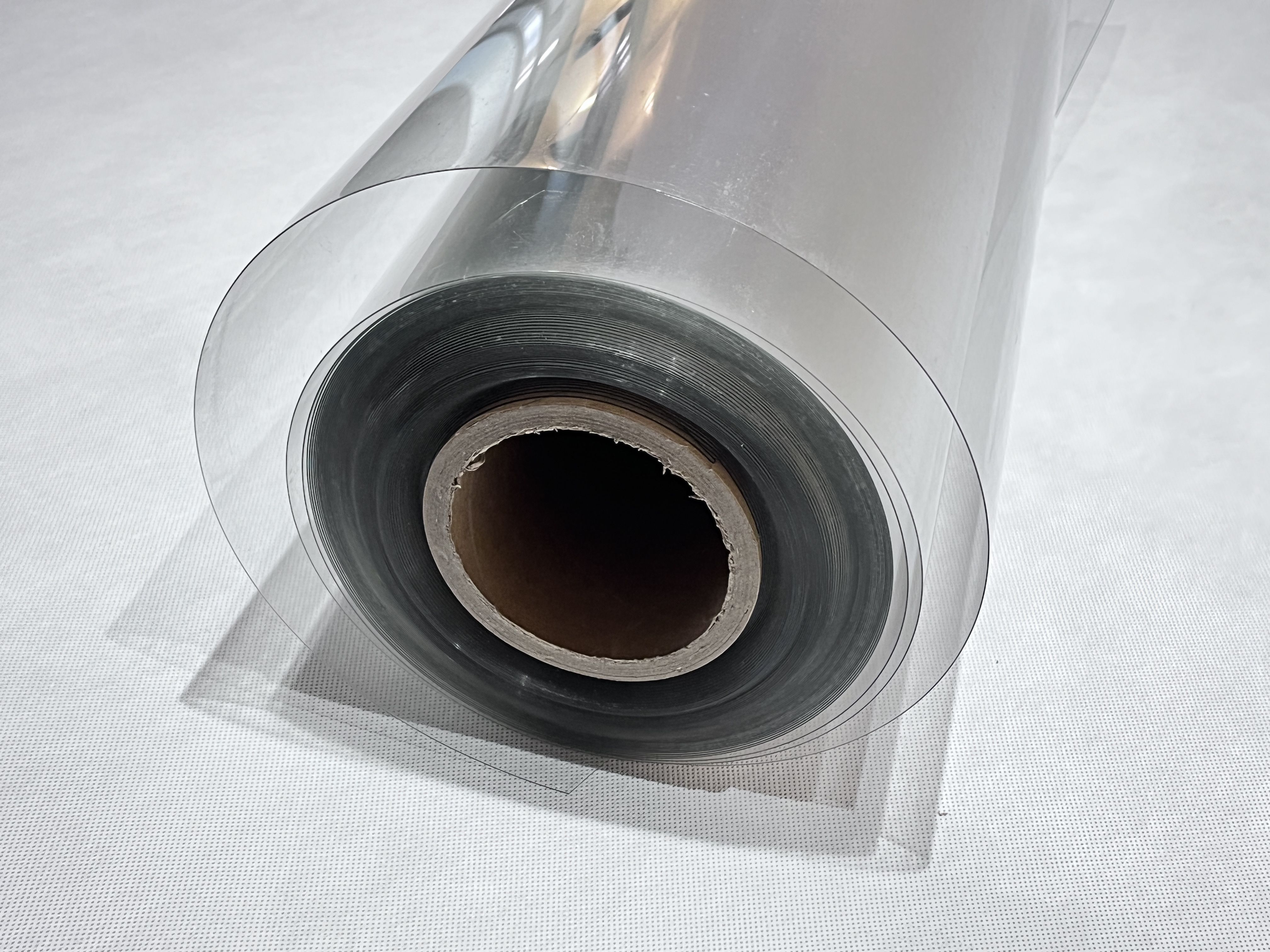

![PET Transparent Sheet (11)]()

In addition, PET plastic has excellent abrasion resistance, dimensional stability, and electrical insulation. Bottles made of PET have high strength, good transparency, non-toxicity, anti-penetration, lightweight and high production efficiency, so they have been widely used. The molecular chain structure of PBT is similar to that of PET, and most of its properties are the same, except that the main chain of the molecule has changed from two methylene groups to four, so the molecule is more flexible and the processing performance is better.

PET Features

PET is a milky white or light yellow highly crystalline polymer with a smooth and shiny surface. PET has the following features:

![PET Transparent Sheet (1)]()

1. It has good creep resistance, fatigue resistance, friction resistance and dimensional stability, low wear and high hardness, and has the largest toughness among thermoplastics.

2. Good electrical insulation performance, small temperature influence, but poor corona resistance.

3. Non-toxic, weather-resistant, chemical resistant, low water absorption, resistant to weak acids and organic solvents, but not resistant to hot water immersion and alkali.

4. The glass transition temperature of PET resin is high, the crystallization speed is slow, the molding cycle is long, the molding cycle is long, the molding shrinkage rate is large, the dimensional stability is poor, the crystallization molding is brittle, and the heat resistance is low.

Lamination PET characteristics

Through the improvement of nucleating agent, crystallizing agent, and glass fiber reinforcement, PET has the following characteristics in addition to the properties of PBT:

![pet-roll-sheet-1 pet-roll-sheet-1]()

1. The heat distortion temperature and long-term use temperature are the highest among thermoplastic general engineering plastics.

2. Because of its high heat resistance, the reinforced PET is immersed in a solder bath at 250°C for 10s without deformation or discoloration, which is especially suitable for preparing soldered electronic and electrical parts.

3. The bending strength is 200MPa, the elastic modulus is 4000MPa, the creep resistance and fatigue resistance are also very good, the surface hardness is high, and the mechanical properties are similar to those of thermosetting plastics.

4.Since the price of ethylene glycol used in the production of PET is almost half cheaper than that of butanediol used in the production of PBT, PET resin and reinforced PET are the lowest price among engineering plastics and have high-cost performance.

Various applications of PET

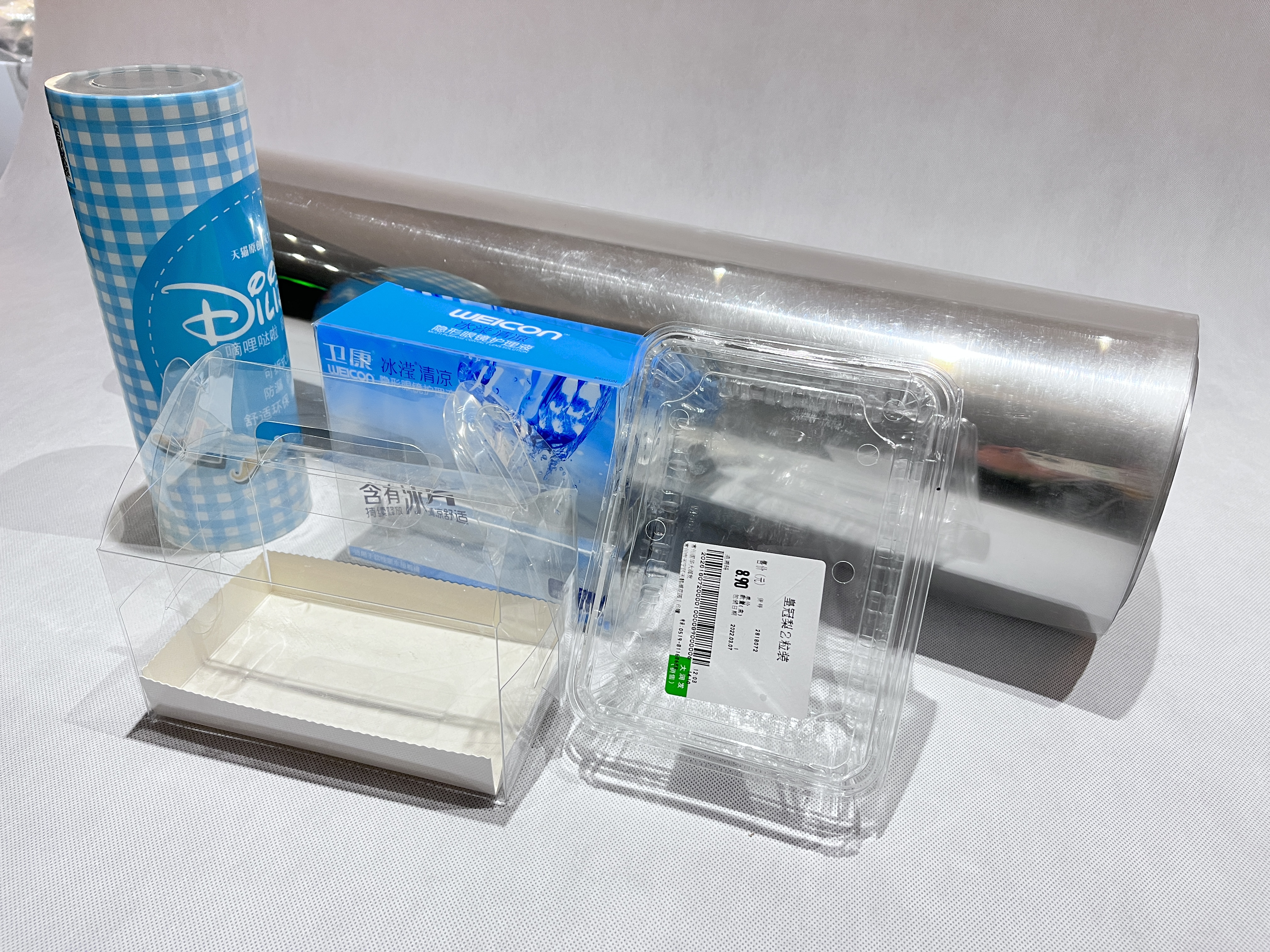

![pet-application-1]() The molding process of PET plastic can be injection molding, extrusion, blow molding, coating, bonding, machining, electroplating, electroplating, vacuum metal plating, and printing. So, PET can be applied to all walks of life.

The molding process of PET plastic can be injection molding, extrusion, blow molding, coating, bonding, machining, electroplating, electroplating, vacuum metal plating, and printing. So, PET can be applied to all walks of life.

1. Film sheet: all kinds of food, medicine, non-toxic and sterile packaging materials; high-grade packaging materials for textiles, precision instruments, electrical components; audiotapes, videotapes, film films, computer floppy disks, metal coatings, photosensitive films, and other substrates; electrical insulating materials, capacitor films, flexible printed circuit boards and membrane switches and other electronic fields and mechanical fields.

2. Application of packaging bottles: Its application has developed from the first carbonated beverage to the current beer bottle, edible oil bottle, condiment bottle, medicine bottle, cosmetic bottle, etc.

3. Electronic appliances accessories: manufacturing connectors, coil bobbins, integrated circuit housings, capacitor housings, transformer housings, TV accessories, tuners, switches, timer housings, automatic fuses, motor brackets, relays, etc.

4. Auto parts: switchboard covers, ignition coils, various valves, exhaust parts, distributor covers, measuring instrument covers, small motor covers, etc. PET also can be manufactured as exterior parts for automobiles.

5. Mechanical equipment: manufacturing gears, cams, pump housings, pulleys, motor frames, and clock parts, also can be used as microwave oven baking trays, various ceilings, outdoor billboards, and models, etc.

English

简体中文

繁體中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

Azərbaycan dili

Bamanankan

Euskara

Беларуская мова

भोजपुरी

Bosanski

Български

Català

Cebuano

Corsu

ދިވެހި

डोग्रिड ने दी

Esperanto

Eʋegbe

Frysk

Galego

ქართული

guarani

ગુજરાતી

Kreyòl ayisyen

Hausa

ʻŌlelo Hawaiʻi

Hmoob

íslenska

Igbo

Ilocano

Basa Jawa

ಕನ್ನಡ

Kinyarwanda

गोंगेन हें नांव

Krio we dɛn kɔl Krio

Kurdî

Kurdî

Кыргызча

Lingala

Lietuvių

Oluganda

Lëtzebuergesch

Македонски

मैथिली

Malagasy

മലയാളം

Malti

मराठी

ꯃꯦꯇꯥꯏ (ꯃꯅꯤꯄꯨꯔꯤ) ꯴.

Mizo tawng

Chichewa

ଓଡ଼ିଆ

Afaan Oromoo

پښتو

ਪੰਜਾਬੀ

Runasimi

Gagana Samoa

संस्कृत

Gaelo Albannach

Sepeti

Sesotho

chiShona

سنڌي

Soomaali

Basa Sunda

Wikang Tagalog

Тоҷикӣ

Татарча

తెలుగు

ትግንያውያን

Xitsonga

Türkmençe

संस्कृत

ئۇيغۇرچە

Cymraeg

isiXhosa

ייִדיש

Yorùbá

isiZulu